Keeping It Cool: Fighting Overheating From Fans to Hot and Cold Aisle Containment

Keeping It Cool: Fighting Overheating From Fans to Hot and Cold Aisle Containment

Despite how and why it is produced, excessive heat has long posed a problem for users of machines. When an energy source, such as electricity, is used to provide power to a machine, it is typical to all energy sources to be released in the form of heat. The results of overheating are damage to the equipment used as well as any nearby components and energy waste. The problem of overheating has been addressed in many forms over time.

The most simple approach to combating overheating is probably the use of a fan near or inside the machine; probably the most common as well. Fans are commonly found in machines of various designs, but perhaps the most familiar fans can be found in desktop computers in the form of an exhaust fans. In the desktops, case-mounted fans are generally found in the rear of the machine, placed there to draw the heat from the interior of the case and propel it outward through a vent. Other fans, aside from the exhaust fan mentioned, may also be at work in various areas inside the case, such as the central processing unit, the graphics card, or the chip set. Other computer fans may be used to draw cooler air into the case or draw warmed air across a heat sink to be cooled.

Heat Sinks

A heat sink is a component, which works to transfer heat, generated by a device to a fluid medium, generally air or a liquid, in order to regulate the device’s temperature. Heat sinks are often found in computers, typically in the area of the central processing unit or graphics processors, where a great deal of energy is being consumed and heat is produced as a result. Today’s applications, often with enhanced video generation, tend toward using a lot of processing power, which can present a difficulty in keeping them cool. While most heat sinks in ordinary desktops will not need more than air to cool off the interior parts, machines which operate intense and complicated graphics mat need to use a liquid such as water or oil to properly disperse excess heat.

When it comes to computing, liquid cooling tends to be more efficient than other options because it removes the heat from the source and delivers it to a secondary cooling surface, generally a cold plate with optimal radiator in accompaniment. This application allows for the use of larger fans to be used at lower operating speeds, reducing noise and excess heat. Since liquid cooling needs a pump, a radiator and piping to control the temperature properly, the costs involved can be more expensive. Another problem is the increased risk of damage due to spillage. However, liquid cooling is increasingly popular in the care for supercomputers and data centers because of the easier maintenance required.

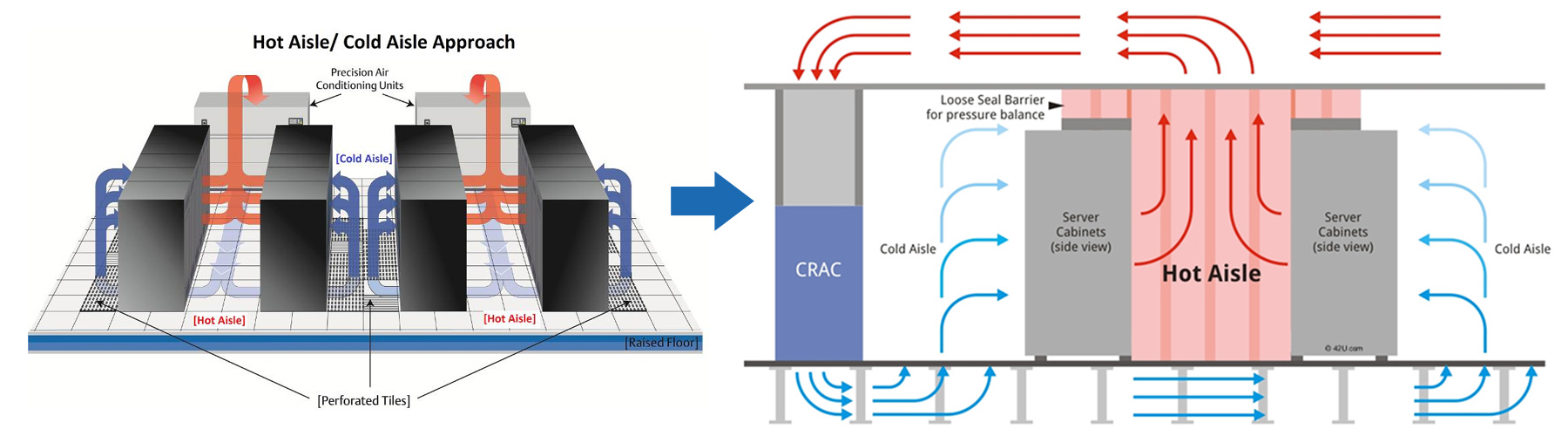

When it comes to these data centers, other cooling methods can be applied such as fans, venting, and air conditioning. Even so, cooling a large facility that generates a regular amount of hot air can still be difficult because stacking so many machines in operation together can create a fair amount of concentrated heat. A designer laying out a floorplan for a data center must always pay heed to the control of airflow, essential to the prevention of the heat gathering in one area. With these factors in mind, data center managers are increasingly selecting a technique called aisle containment.

The general objective of aisle containment is to prevent cooler air from combining with the warmed exhausted air in the server rooms. There are numerous ways to accomplish this but the main method is to aim the exhaust ends of the devices at each other, across the aisle, creating what is referred to as hot and cold aisle containment. With this alignment, alternating aisles of cool and warm air are created, separating the two temperatures from the mere design. This allows the focus of cooling systems to rest on cooling only half the number of aisles or rows that might need to be in a more customary alignment.

Aisle Containment Efficiency

There are numerous ways in which aisle containment can be used with greater efficiency. For example, blanking panels, PVC curtains or hard panel boards are some of the materials which can be used to create an actual physical barrier between the alternating aisles. They may also be used to augment the air flow. Using a raised floor can also be useful because it can allow the cooled air from a chiller or air conditioner to be delivered directly to areas where the heat is most.

These methods of beating the heat when it comes to machine performance are varied and may need to be fine-tuned with consideration to one’s environment but are nonetheless effective in most situations, alone or combined.

For questions or concerns regarding aisle containment and cooling solutions, please feel free to contact our Cool Shield support staff anytime at +1-866-740-2121.

(Updated on: Jan 28, 2019 @ 4:13 pm)