Aisle Containment Systems

Build-to-Suit Aisle Containment Solutions by CoolShield

CoolShield has been an industry leader in the aisle containment industry since 2010. Lean on our experience and expertise. Our containment solutions can be built to suit any size data center.

What is Aisle Containment?

Aisle containment is a cooling system that completely separates the cold supply airflow from the hot equipment exhaust air.

Aisle containment creates an even and consistent supply intake temperature for data center equipment and electronics. The returning air is warmer and drier when it reaches the AC coil.

Why is Aisle Containment so Important?

Aisle containment is an important environmental control standard in the data center industry because it removes the risk of servers and other sensitive electronics from overheating, which in turn saves companies upwards of thousands of dollars in energy costs a year. With a proper containment system in place the data center manager’s ability to fully separate cold airflow from exhaust air coming from hot equipment is an option that can be monitored precisely. The result is a supply temperature that is uniform and predictable.

There can be either hot or cold containment implemented, depending on your particular facility’s layout.

Active data centers run extremely hot. The worst enemy of a data center is a non-monitored, poorly designed system without a sufficient cooling system in place. Servers have their own internal cooling mechanisms, but the hot air from the surrounding environment still makes its way into the server intakes. The result is overheating, which results in reduced server performance and/or equipment damage due to excessive heat. The only solution to maintaining a constant temperature is aisle containment.

The data center manager’s primary responsibilities is to keep the machines operating at an ideal temperature, which is between 70° and 75° F. A lay person would suggest that a manager could simply cool the entire room. For many reasons, this is both inefficient and costly. Many data centers and server farms are extremely large structures with a plethora of air that needs constant cycling. Furthermore, the costs of managing a data center skyrockets as these facilities became larger and more complex.

Learn more about Cold Aisle Containment

Learn more about Hot Aisle Containment

HAC vs CAC

Hot Aisle Vs Cold Aisle Containment Systems

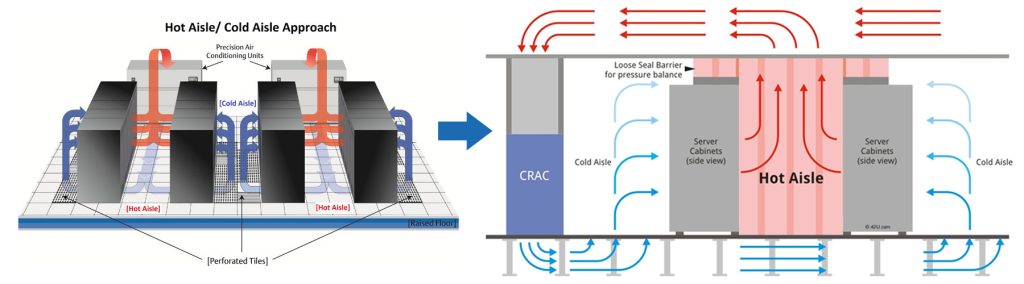

Aisle containment is a layout design for server racks and other computing equipment in a data center. The goal of a hot or cold aisle configuration is to conserve energy and lower cooling costs by managing air flow.

Designing the proper containment system requires lining server racks in rows (or aisles) with the cold air intakes facing one direction and hot air exhaust facing the other. This makes one side of the row hot and the other side cold.

The system is built around an CRAC (Computer room air conditioning unit) AC unit. The cold air intake side of the row faces the CRAC output ducts.This is the cold aisle. The hot aisle is where the hot side of the row typically pours into the CRAC intake. Cooling capacity will increase. Keeping these aisles separated from one another is the core of containment.

Proper aisle containment creates a physical barrier that separates the hot and cold air from mixing. Containment panels or strips create a partition to isolate either the server supply air (cold aisle) or the exhaust air (hot aisle). Preventing the supply and exhaust air from mixing significantly increases the capacity and cooling efficiency of the cooling infrastructure.

Some data centers focus on one or the other. Site conditions dictate the best approach. At most sites, it is easier to implement a cold aisle containment system because there are typically cable trays and other obstructions above the hot aisle. It is very difficult to implement a hot aisle system if there is not a return plenum.

Containment Structure

The Cool Shield Aluminum Channel

The aluminum channel is the heart of any aisle containment system. The proprietary combination of slotted and threaded sides has proven incredibly versatile for use in containment ceiling panels, vertical panels, containment walls, doors and more. There are several versions of the channel to specifically meet any design criteria.

Why Our Containment Solutions Are the Best

Quality Materials and Design

Cool Shield containment channels use high-quality 6063 aluminum alloy with a durable two-step anodization process. Available in clear, black, or powder coated in custom colors. In addition, we manufacture standard brackets with 11-gauge galvanized steel for superior strength. Cool Shield offers both flexible aisle containment strip and containment panel solutions that comply with National Fire Protection Association (NFPA) 75 standards. Our standard polycarbonate and strip materials feature ASTM International E-84 Class A ratings. We also offer FM 4910-approved solid panels in clear and opaque finishes.

Sliding and hinged containment doors are fabricated with post-formed steel frames for maximum sturdiness and performance when putting an aisle containment system in place. Hardware such as hinges, rollers and handles provide lasting functionality. Doors are designed to meet applicable Americans with Disabilities Act (ADA) requirements.

In addition, our aisle containment accessories including blanking panels, foam strips and cable covers feature UL94-V0, the highest rating available for this type material.

How Our Containment Works

Aisle Containment Capabilities Video

Frequently Asked Questions

Aisle Containment FAQs

Can I install my own aisle containment solutions?

How do drop away panels work?

Does Cool Shield offer FM Global rated solutions?

Does Cool Shield have solutions which meet NFPA 75 requirements?

What is NFPA 75?

Can I use fusible links to prevent my strips or panels from obstructing fire suppression?

What are fusible links?

How will aisle containment affect my fire suppression system?

Can I attach the containment system to my drop ceiling grid?

Which is better, hot aisle containment or cold aisle containment?

The short answer is that both HAC and CAC are nearly equally effective because they prevent supply and exhaust air from mixing. Cold aisle containment (CAC) provides excellent control over supply temperatures to optimize CRAC set points. Hot aisle containment (HAC) returns warmer air to CRAC units which can increase cooling capacity. The best approach for your data center will be dictated by your site conditions. At most existing sites, it is easier to implement a CAC solution because there are typically cable trays and other obstructions above the hot aisle. It is also very difficult to implement hot aisle containment if there is not a return plenum. Our Project Managers can help you determine which approach would be most effective in your data center.